Brickworks and Tileries of Stoke-on-Trent and district

|

|

|

|

Brickworks and Tileries of Stoke-on-Trent and district |

|

The Good Old Way

A little book about the

Springfield Tileries

Newcastle-under-Lyme

showing that in tile

making the good old

way is still the best

Page 11

browse the booklet by clicking 'next' or use the page list below

|

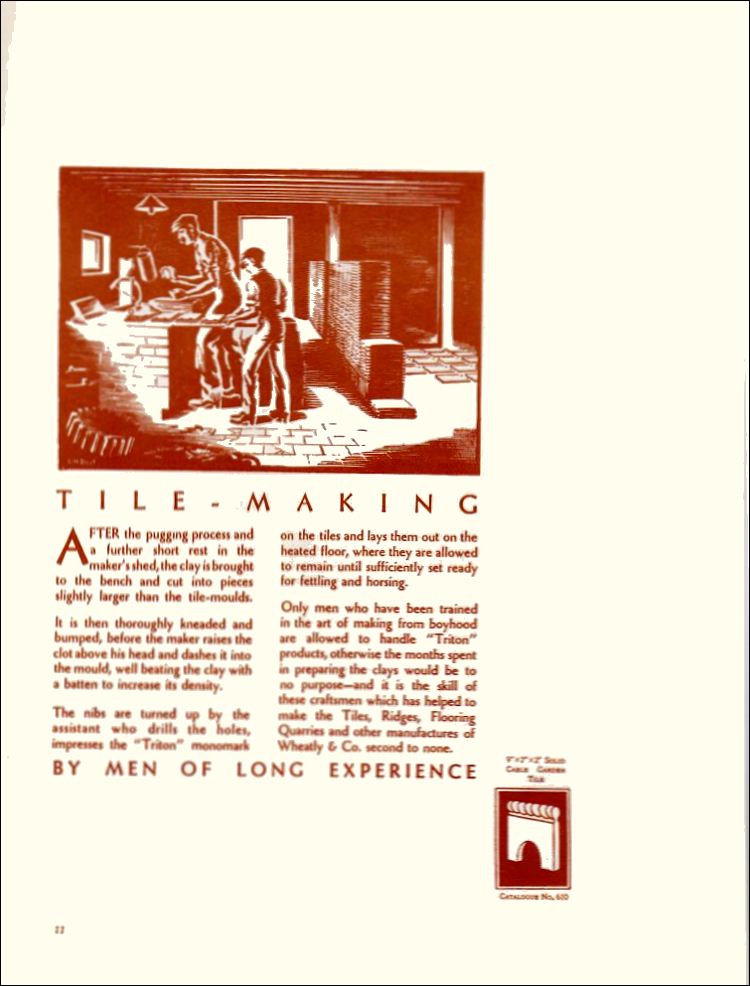

Tile - Making

It is then thoroughly kneaded and bumped, before the maker raises the clot above his head and dashes it into the mould, well beating the clay with a batten to increase its density. The nibs areturned up by the assistant who drills the holes, impresses the "Triton" monomark on the tiles and lays them out on the heated floor, where they are allowed to remain until sufficiently set ready for fettling and horsing. Only men who have been trained in the art of making from boyhood are allowed to handle "Triton" products, otherwise the months spent in preparing the clays would be to no purpose - and it is the skill of these craftsmen which has helped to make the Tiles, Ridges, Flooring Quarries and other manufactures of Whetly & Co. second to none. By Men of Long Experience |