Brickworks and Tileries of Stoke-on-Trent and district

|

|

|

|

Brickworks and Tileries of Stoke-on-Trent and district |

|

The Good Old Way

A little book about the

Springfield Tileries

Newcastle-under-Lyme

showing that in tile

making the good old

way is still the best

Page 13

browse the booklet by clicking 'next' or use the page list below

![]()

![]()

|

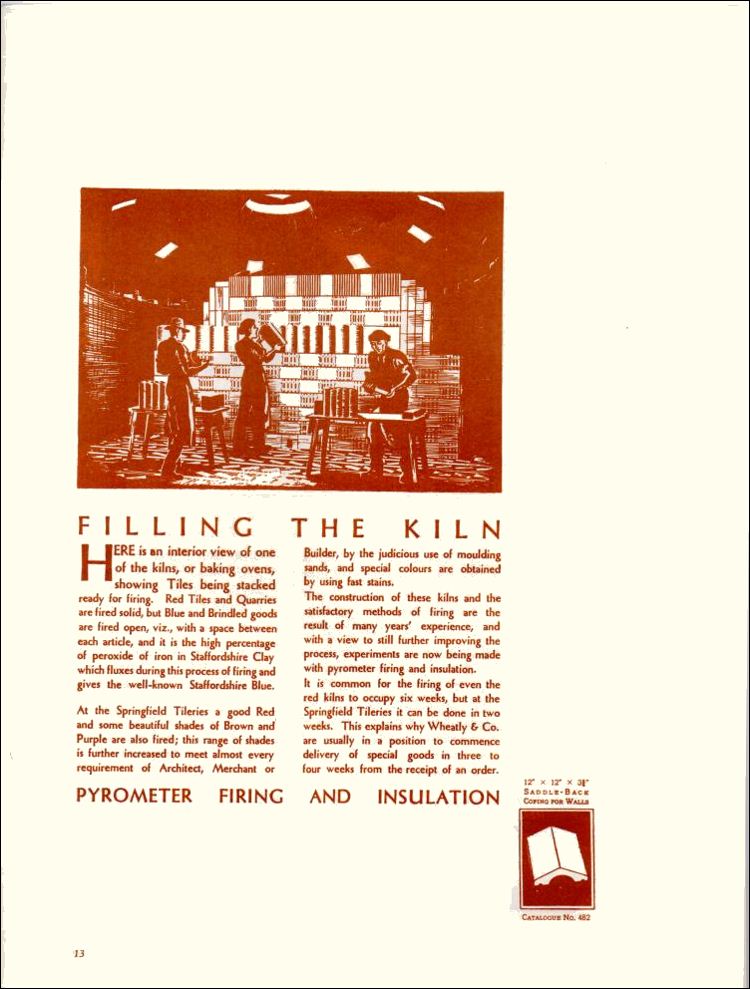

Filling the Kiln

At the Springfield Tileries a good Red and some beautiful shades of Brown and Purble are also fired; this range of shades is further increased to meet almost every requirement of Architect, Merchant or Builder, by the judicious use of mouldin sands and special colours are obtained by using fast stains. The construction of these kilns and the satisfactory methods of firing are the results of many years experience, and with a view to still further improving the process, experiments are now being made with pyrometer firing and insulation. It is common for the firing of even the red kilns to occupy six weeks, but at the Springfield Tileries it can be done in two weeks. This explains why Wheatly & Co. are usually in a position to commence delivery of special goods in three to four weeks from the recipt of an order. Pyrometer Firing and Insulation |