Brickworks and Tileries of Stoke-on-Trent and district

|

|

|

|

Brickworks and Tileries of Stoke-on-Trent and district |

|

The Good Old Way

A little book about the

Springfield Tileries

Newcastle-under-Lyme

showing that in tile

making the good old

way is still the best

Page 9

browse the booklet by clicking 'next' or use the page list below

|

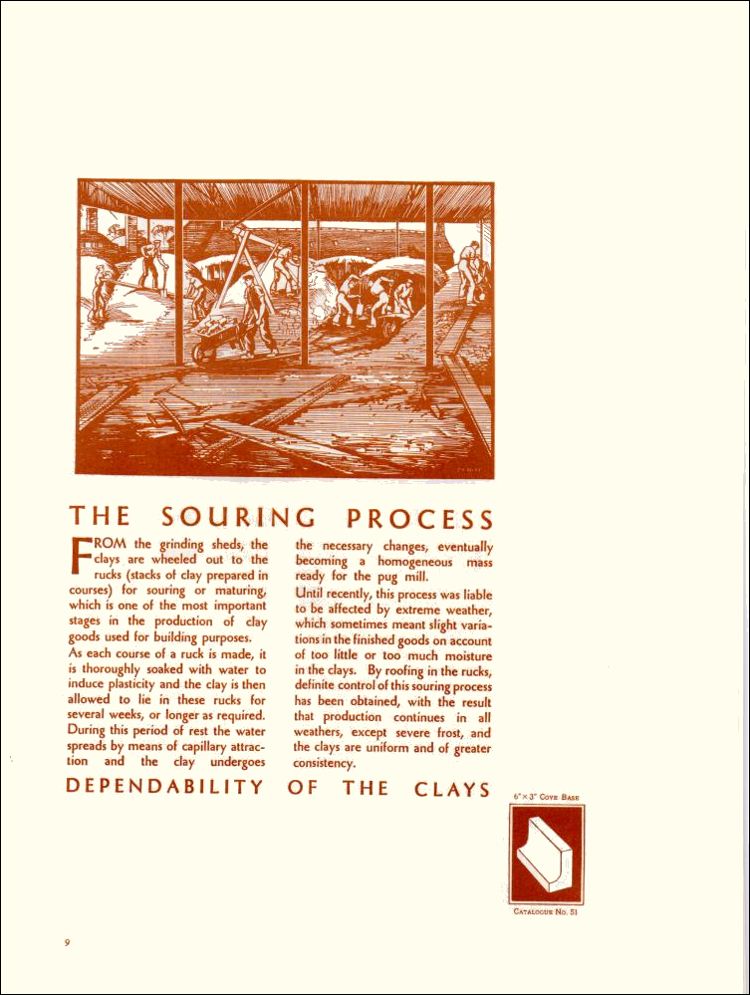

The Souring Process

As each course of a ruck is made, it is thoroughly soaked with water to induce plasticity and the clay is then allowed to lie in these rucks for several weeks, or longer as required. During this period of rest the water spreads by means of capillary attraction and the clay undergoes the necessary changes, eventually becoming a homogeneous mass ready for the pug mill. Until recently, this process was liable to be afected by extreme weather, which sometimes meant slight variations in the finished goods on account of too little or too much moisture in the clays. By roofing in the rucks, definite control of this souring process has been obtained, with the result that production continues in all weathers, except severe frost, and the clays are uniform and of greater consistency. Dependability of the Clays |