The Middleport Pottery of

Burgess and Leigh (opened 1888)![]()

![]()

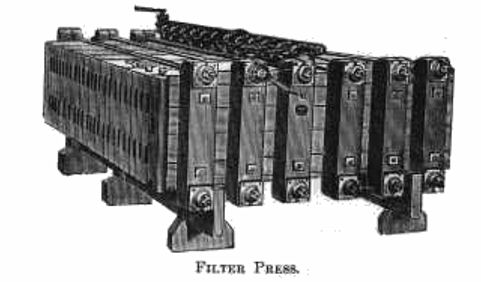

Filter press

![]()

![]()

![]()

Next: the filtered clay

Previous: the

blunger

At this point the slip (liquid clay), which was now free of grit and impurities, was converted back into useful clay for pottery manufacture by removing the excess water.

This used to be done by evaporation, a long and tedious process.Burgess and Leigh installed the latest equipment in their modern factory and William Boulton engineers produced a filter press, of the type shown below. This press quickly removed the water from the slip.

The filter press

the cast iron press plates were forced together and the excess water

driven out of the clay, through the press cloths

The filter press as

originally designed by William Boulton

"The system of filtering

clay instead of boiling it on evaporating kilns

is one which Mr. Boulton (although not the original inventor) has introduced

very largely,

and considerably improved the pressure pump and construction of the

presses.

The old system of evaporation occupied a considerable space in a manufactory,

and was very costly

in fuel, labour and repairs, and the clay produced was not so good."

from an 1893 trade journal