The Middleport Pottery of

Burgess and Leigh (opened 1888)![]()

![]()

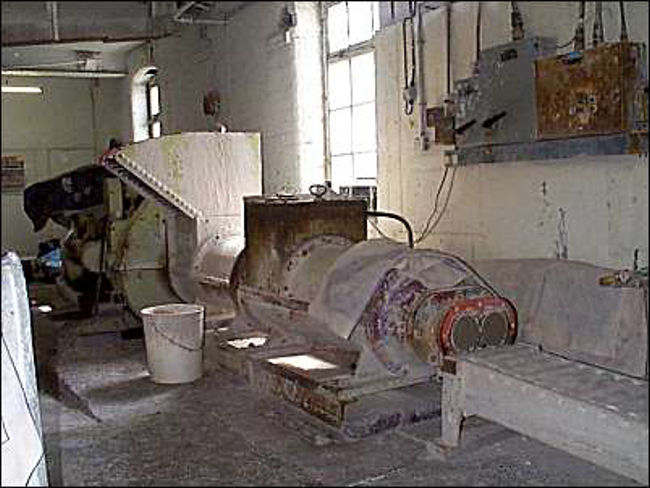

The pug mill - removes the air from the clay

![]()

![]()

![]()

Next: the yard between the factory buildings

Previous: the

filtered 'cakes' of clay

The pug mill mixed the filtered clay 'cakes' and then extruded it into 'sausages' - this gave a uniform clay and removed the air. When the clay came out of the pug mill it was cut into small balls for working into flatware (plates, saucers etc.) and hollowware (cups, bowls, dishes etc.)

Before the pug mill was invented the air was removed from the clay by throwing or 'wedging' it. It was a tiring manual job (often carried out by children).

The following is an 1840/41 testimony of a clay thrower who worked for Mintons (a pottery works in Stoke):

EARTHENWARE FACTORY, Eldon Place, Stoke;

Proprietors Messrs. MINTON and BOYLE.HOT-HOUSE and THROWING ROOM. Temp. 94 Fahren., open air 42. No. 2: Thomas Kay, aged 46 I have worked for Mr. Minton 18 years next Christmas. Slip-making in the fore part of my service, that is making the clay for use; I now look to the ware in the hot-house; besides that I beat the clay in the adjoining room; beating clay is tremendous hard work; I stand near the open door to do that; the hottest work is in the hot-house; don't keep a thermometer there; heat rises from 90º to 120º; 'tis not so hot now by a deal as in the morning; we cool it now for the ware.

I am paid by the quantity of work done; my average wages are about 15s. per week. I have a wife and 7 children; only one is a potter. I come to work at 6 in the morning, sometimes at 5; it depends upon what goods are in heat; leave at 3, 4, 5, and 6; and afterwards do a little job-work for another master, and earn 4s. or 3s. a-week.

Don't find the great change of heat affect my health; it sometimes affects others; very few live to any age in such an employment, 'tis the hardest business of potting. I live at Harford Bridge; do not go home to dinner; I take my dinner in the throwing- house; get bread and cheese, no ale; but get some meat at home at night; can't read or write.

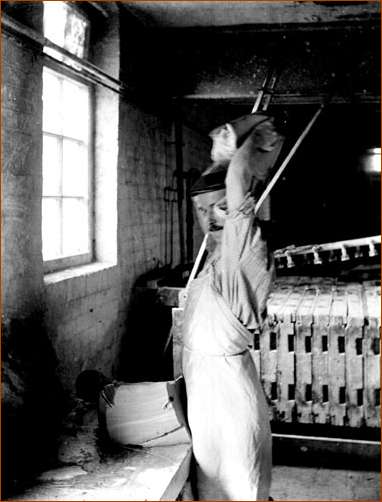

Date: 1900

- 1910 (c.)

Portrait of a pottery worker known as a clay wedger at work.

This lantern slide appears to be one of a group used for a presentation or slide

show by Blake entitled "Staffordshire Pottery."

"The Clay Wedger. Plastic clay as removed from the

filter is taken in lumps of about a cwt,

cut in two, one half raised to arms length and dumped into the other half.

This is continued until the mass is kneaded to a consistency fit for pottery

making."

The pug mill at Burgess and Leigh

did away with

the need for the air to be removed from the clay by 'throwing' it.

Twin 'sausages' of clay about to

emerge from the pug mill

The pug mill as

originally designed by William Boulton

"Another machine of Mr.

Boulton's, which has considerably

improved the quality of tho day, and dispensed with a good deal

of hard labour, which frequently fell upon juveniles, is the pug

mill for consolidating the clay."

from an 1893 trade

journal

![]()

![]()

![]()

Next: the yard between the factory buildings

Previous: the

filtered 'cakes' of clay