The Middleport Pottery of

Burgess and Leigh (opened 1888)![]()

![]()

The transfer shop - applying the transfer to the ware

Previous: the fettling shop

Next: the view from the front window

Moving across the yard from the packing shop to the first floor transfer shop.

Transfer printing was developed in response to a call by English consumers for less expensive, mass produced wares. Customers wanted embellishment on their previously plain utilitarian wares. Initially the patterns were oriental in flavour.

Transfer printing is a process by which a pattern or design is etched onto a copper (or other metal) plate. The plate is then inked and the pattern is "transferred" to a special tissue. The inked tissue is then laid onto the already bisque fired ceramic item, glazed, and fired again.

Applying transfer to teapots |

Applying transfer to large bathroom set jug |

|

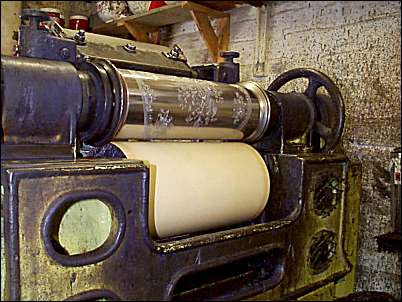

The transfer printing

machine: At the top end of the transfer room is the printing machine. There is an engraved metal roll which carries the ink, the pattern is then 'transferred' onto paper and then onto the ware.

|

|

The transfer printing machine |

Detail of the engraved metal roll |

|

|

|

After printing the transfer papers are put onto the overhead pulley wire and sent down the shop for the potters to apply to the ware |

ware with the transfer applied is put on a conveyor belt at the end of the shop the paper is washed off leaving the pattern on the ware - this is then glazed and fired. |

![]()

![]()

![]()

Previous: the

packing shop

Next: the view from the front window