The Middleport Pottery of

Burgess and Leigh (opened 1888)![]()

![]()

Messrs. Burgess and Leigh, Pottery Manufacturers, Middleport Pottery, Burslem

from an 1893 advertising and trade journal.

![]()

![]()

![]()

Next: The factory frontage

Previous: Introduction and location maps

Messrs. Burgess and Leigh,

Pottery Manufacturers, Middleport Pottery, Burslem

A descriptive

account of The Potteries (illustrated) - 1893 advertising and trade

journal.

|

Messrs, Burgess and

Leigh, Pottery Manufacturers, Middleport Pottery Burslem. "The story of the development of the potter's art in ancient and modern times, and amongst nations differing widely in their ideas and character, is as fascinating as it is instructive and significant. That in all essential points, and particularly on the artistic side, the art was carried by the ancients to a level of perfection, rarely, if ever reached in these utilitarian days, is obvious to any visitor to home or foreign museums where the ancient masterpieces are exhibited. Modern discovery has done something, too, to advance the industry, and the story of Palissy is as noteworthy as any other in the whole history of discovery, and valuable as marking the transition from brown to white which distinguishes the modern from all ancient productions. Of how vast commercial value this department of production has become in our times, any visitor to "the Potteries." may easily find proof enough, but not the least pleasant feature of the present condition of the industry is the successful effort made by so many firms in special departments.

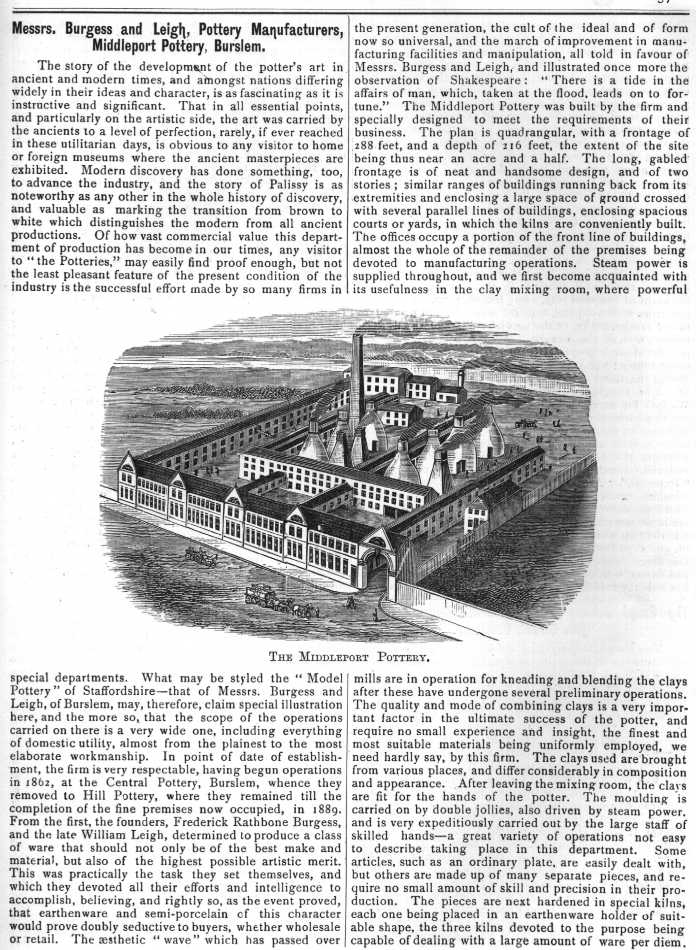

The aesthetic "wave" which has passed over the present generation, the cult of the ideal and of form now so universal, and the march of improvement in manufacturing facilities and manipulation, all told in favour of Messrs. Burgess and Leigh, and illustrated once more the observation of Shakespeare: "There is a tide in the affairs of man, which, taken at the flood, leads on to fortune." The Middleport Pottery was built by the firm and specially designed to meet the requirements of their business. The plan is quadrangular, with a frontage of 288 feet, and a depth of 116 feet, the extent of the site being thus near an acre and a half. The long, gabled frontage is of neat and handsome design, and of two stories; , enclosing spacious courts or yards, in which the kilns are conveniently built. The offices occupy a portion of the front line of buildings, almost the whole of the remainder of the premises being devoted to manufacturing operations. Steam power is supplied throughout, and we first become acquainted with its usefulness in the clay mixing room, where powerful mills are in operation for kneading and blending the clays after these have undergone several preliminary operations. The quality and mode of combining clays is a very important factor in the ultimate success of the potter, and require no small experience and insight, the finest and most suitable materials being uniformly employed, we need hardly say, by this firm. The clays used are brought from various places, and differ considerably in composition and appearance. After leaving the mixing room, the clays are fit for the hands of the potter. The moulding is carried on by double jollies, also driven by steam power, and is very expeditiously carried out by the large staff of skilled hands—a great variety of operations not easy to describe taking place in this department. Some articles, such as an ordinary plate, are easily dealt with, but others are made up of many separate pieces, and require no small amount of skill and precision in their production. The pieces are next hardened in special kilns, each one being placed in an earthenware holder of suitable shape, the three kilns devoted to the purpose being capable of dealing with a large amount of ware per diem." |

![]()

![]()

![]()

Next: The factory frontage

Previous: Introduction and location maps