![]()

Materials used in the manufacture of Ceramics

Clay

|

Clay |

|

![]()

![]() Clays in the Potteries:

Clays in the Potteries:

In Cobridge, between Burslem and Hanley, yellow clay two feet thick lay only seven feet below the surface with six feet of red marl immediately below that. (This in the vertical shaft of a coal mine). Stoneware clays and fireclays were also found within easy reach. The geological strata of North Staffordshire are unusual and, with vertical faulting and extensive outcropping, a very great variety of clays and coals were available on the surface to anyone who dug a little deeper than usual.

Clay was dug out of the ground until pits were formed which for red clays became known as ‘marl holes’ . In the seventeenth century, potters dug clay out of the roads ( so as not to lose any land area from cultivation): eventually the roads were so dangerous that the offenders were forbidden by law to continue the practice. This was probably the origin of the term ‘pot holes’.

![]() How the clays were used:

How the clays were used:

Red marls were the basic clays used for most early pottery. They were glazed with lead, applied to the dry clay ware as powdered galena (lead sulphide) or ‘Smithum’. Lead provided the gloss, and iron or manganese provided the colour. The ‘pipe-clays’, or white burning clays, were not so abundant and were used more sparingly either to coat the face of an article before decoration - as in slip-trailed ware - or in small amounts as the decoration itself. Later, mugs and jugs had a thin coating of white slip over the dark clay to render them more attractive.

Of the other clays which were found locally, the most useful were the fireclays. This type of clay will withstand intense heat without bending or breaking. Used as bricks for the firemouths and oven lining, it enabled higher temperatures to be achieved with the coal without danger of kiln collapse. Later, when protective containers, called ‘saggars’ became necessary, they were made of fireclay. Red marls of the coarser types were used for making building bricks and tiles - heavy things to transport, so useful to have them available nearby.

Source: Gladstone Museum leaflet.

![]() Marl holes:

Marl holes:

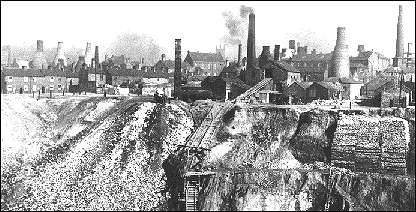

Photo: 1905 Blakes of Longton

Marl hole in Longton, shows the extraction of red firing clay or marl immediately behind the works.

The plateway in the centre took the clay into the heart of the factory. On the left the disused parts of the pit has been filled in with old broken pottery and waste known as 'shraff'.

Note on the left the terraced housing which is so close to the pottery and marl hole.

Photo: Ian BaileyPrivate train and railway of the old Wheatley brickworks taking clay from the marl hole to the works.

![]() North Staffordshire Clay:

North Staffordshire Clay:

Dr R Plot gives the earliest (1686) account* of the clays of the area starting with the brick clays between Newcastle and Keele:

‘which when burnt became all over blue...’ the famous Staffordshire Blue Brick.

'As for tobacco pipe clays they are found all over the county..... And Charles Riggs of Newcastle makes very good pipes of three forts of Clay, a white and a blew, which He has from between Shelton and Hanley green, whereof the blew clay burns the whitest, but not so full as the White ie it shrinks more; but the best sort He has from Grubbers Ash, being whitish mixt with yellow, it is a short britle sort of Clay, but burnes full and white, yet He sometimes mixes it with the blew beforementioned.But the greatest Pottery they have in this County is carryed on at Burslem near Newcastle under Lyme, where for making their severall sorts of Pots, they have as many different sorts of Clay, which they dig round about the Towne, all within half a miles distance, the best being found nearest the coale, and are distinguish’t by their colours and uses as followeth.

1 Bottle clay, of a bright whitish streaked yellow colour.

2 Hard-fire clay of a duller whitish colour , and fuller intersperst with a dark yellow, which they use for their blackwares, being mixt with the

3 Red blending clay, which is of a dirty red colour.

4 White-clay, so called it seems though of a blewish colour and used for making yellow-colour’d ware, because yellow is the lightest colour they make any Ware of all of which they call throwing clays, because they are of a closer texture, & will work on the wheel;'

SOURCES:

* Plot R 1686, The Natural History of Staffordshire.

Oxford.

'The Potteries' - David Sekers.

Gladstone Museum leaflets.

![]()

questions / comments? email Steve Birks steveb@netcentral.co.uk